Your Fast-Track Partner for One-Offs, Legacy Parts & Problem-Solving Castings

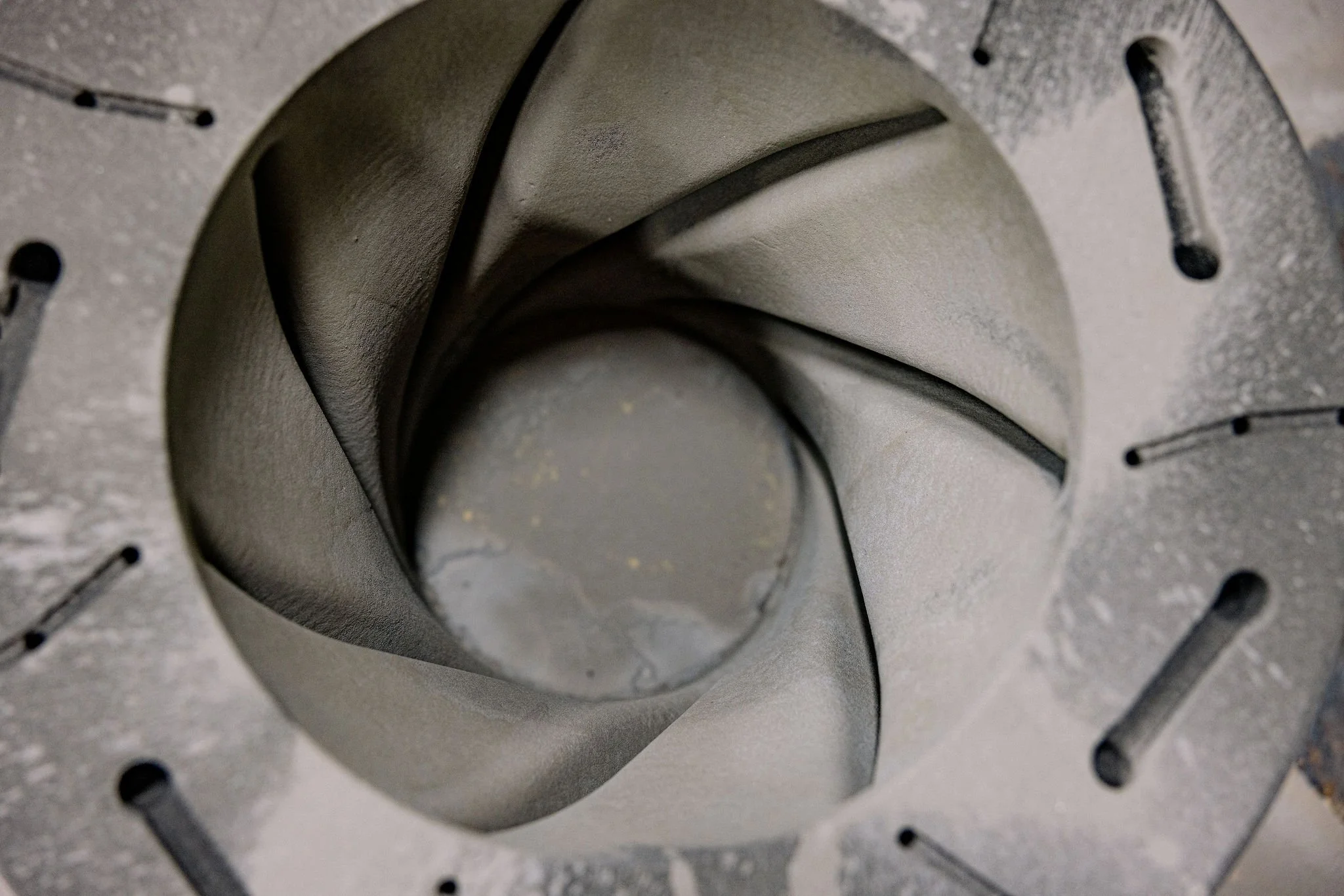

At One Off Castings, we specialize in short-run metal casting and rapid prototyping. Based in Northeast Arkansas, our foundry is driven by a passion for solving complex casting challenges with precision and speed.

What We Offer

At One Off Castings, we specialize in solving complex casting problems through a combination of precision engineering, reverse engineering capabilities, and flexible short-run production. Our team understands the technical demands of legacy part replication, tight-tolerance prototypes, and low-volume metal casting — and we respond with solutions that are practical, fast, and reliable.

Whether you already have a CAD file or need help recreating a part through reverse engineering, we’re built to step in where traditional foundries can’t. While a model is required for production, our team can assist in creating one if needed

What You Can Expect:

Precision & Speed – Dimensional accuracy, fast turnaround, and consistent results

Reverse Engineering Support – Castings reproduced from samples, drawings, or scanned models

Engineer-to-Engineer Collaboration – Clear communication and technical alignment at every step

Capabilities

Metals Poured

-

ASTM A48: 25 A or B, 30 A or B, 35 A or B, 40 A or B

ASTM A278: 25 A or B, 30 A or B, 35 A or B, 40 A or B

ASTM A436: N1B

-

ASTM A536: 100-70-03, 80-55-06, 65-45-12, 60-40-18

ASTM A439: D2

-

ASTM A216: WCB, WCA, WCC

ASTM A352: LCB

-

Item descriptionASTM A351: CF3M, CF8M

ASTM A487: CA6NM CL A or B, CA15 Cl A or B

ASTM A743: CA6NM CL A or B, CA15 CL A or B, CF3M, CF8M

ASTM A744: CF3M, CF8M

ASTM A890: CD4MCuN

ASTM A995: CD4MCuN

-

ASTM B26: 319

ASTM B26: C355

ASTM B26: A356

In-house Aluminum heat treat

All In House

What makes One-Off Casting unique:

We pour a wide range of engineering alloys, including steel, stainless steel, iron, and aluminum.

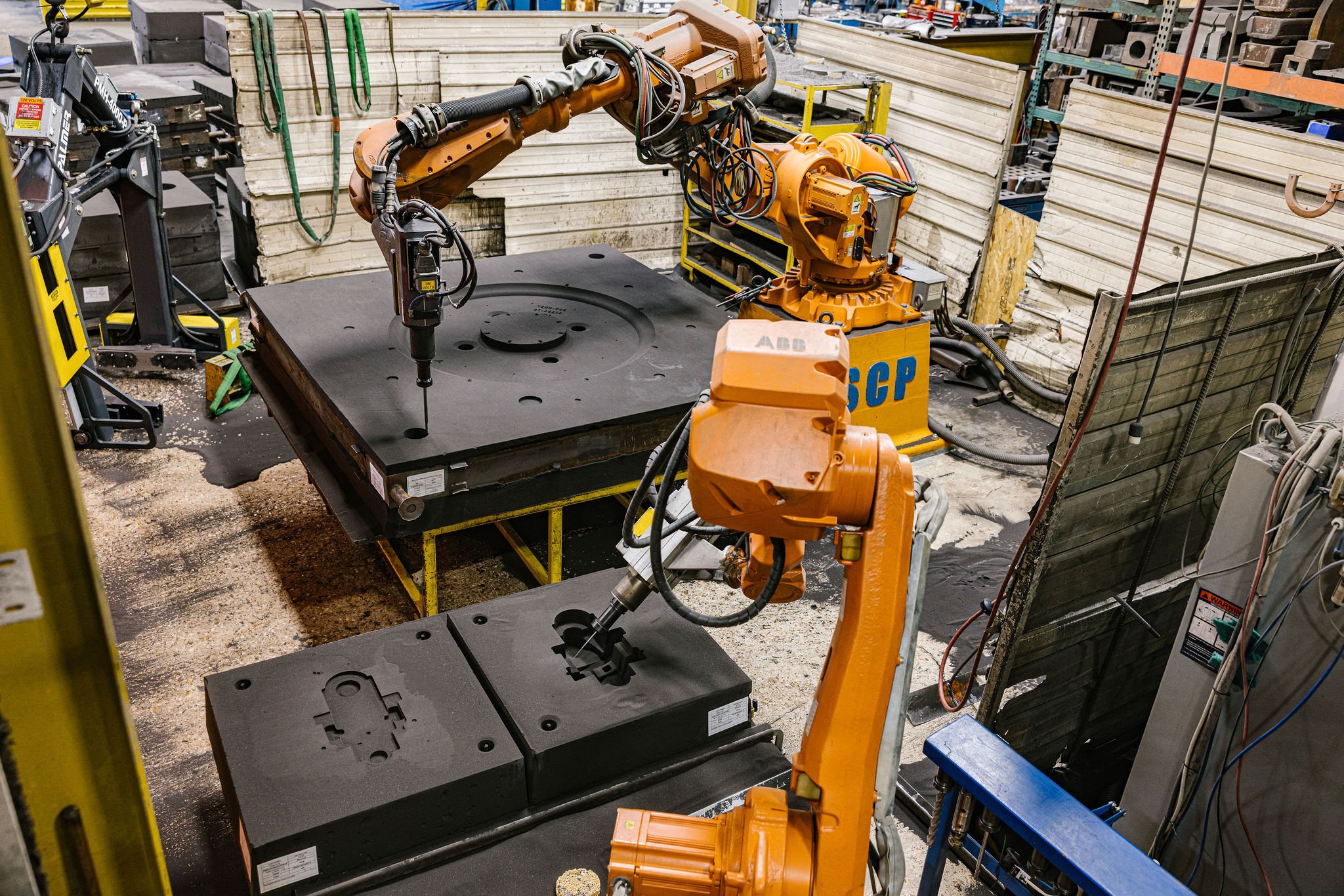

Four in-house robotic molders for increased casting precision and production efficiency.

In-house 3D sand printer for advanced mold-making capabilities.

We use 100% silica-free ceramic sand (Carbo) for superior casting quality and surface finish.

Full in-house heat treatment to enhance and control material properties.

Certified in-house inspection processes, including Liquid Penetrant (LPI) and Magnetic Particle Inspection (MPI).

In-house spectrometers ensure accurate chemical composition analysis.

In-house tensile bar testing for mechanical property validation.

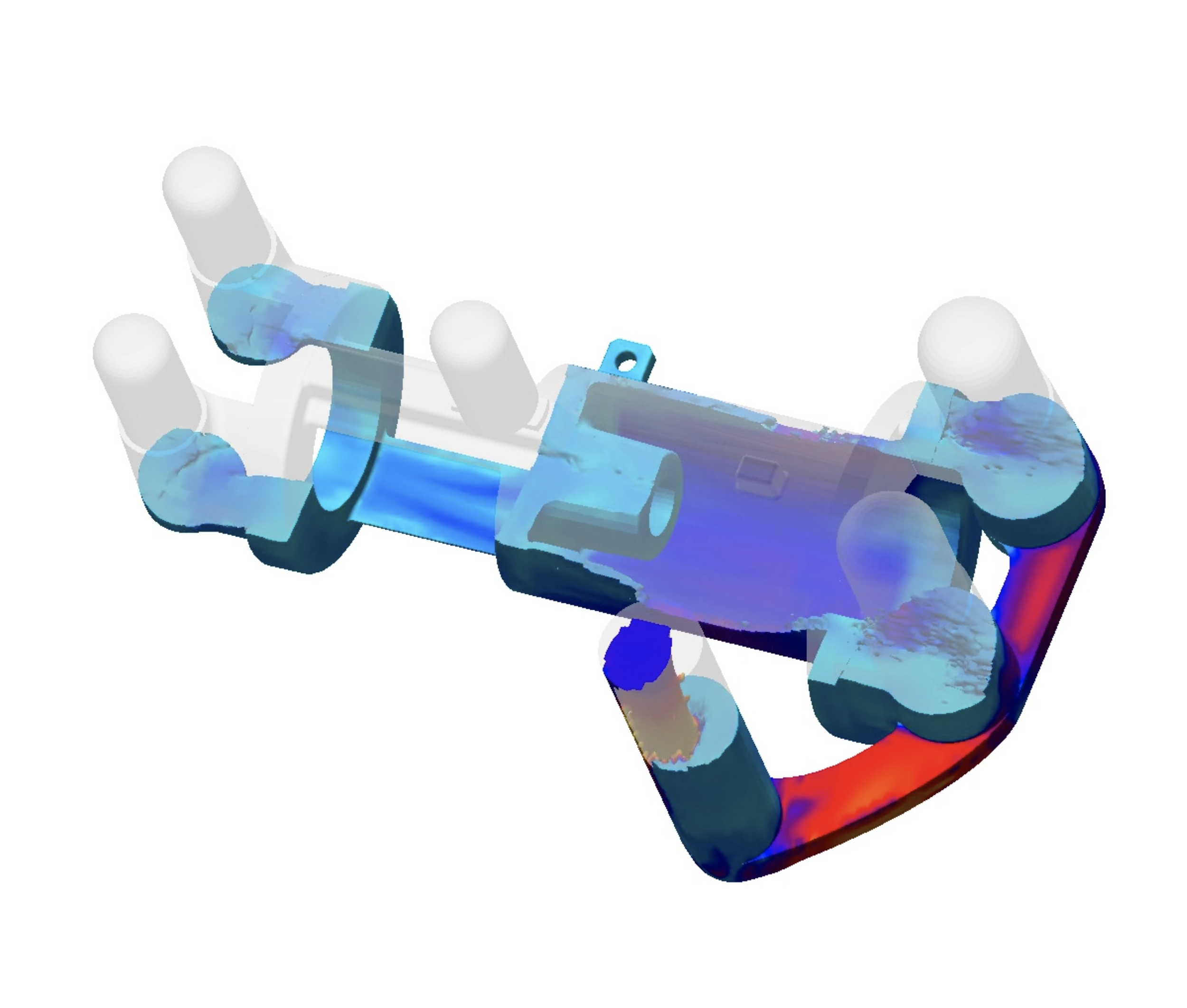

Advanced casting simulations using in-house MAGMA and NovaCast software.

Seamless integration across engineering, simulation, mold production, pouring, and heat treatment—all under one roof.