Streamlined Prototyping Solutions

One Off Castings offers rapid prototyping services for custom metal parts in the U.S., specializing in prototype aluminum castings, low-volume production, and fast-turn tooling using 3D sand printing and modern foundry methods

At One Off Castings everything is based on a 3D model, allowing for easy modifications. Each mold is unique to the model, eliminating costly pattern change fees or expensive machining operations. We pour several different alloys to ensure flexibility in design and performance, meeting your specific needs.

-

Our experienced engineers provide detailed castability recommendations and conduct solidification simulations to ensure your prototype meets the highest performance standards. From design review to process optimization, we guide you through every step of the prototyping journey.

-

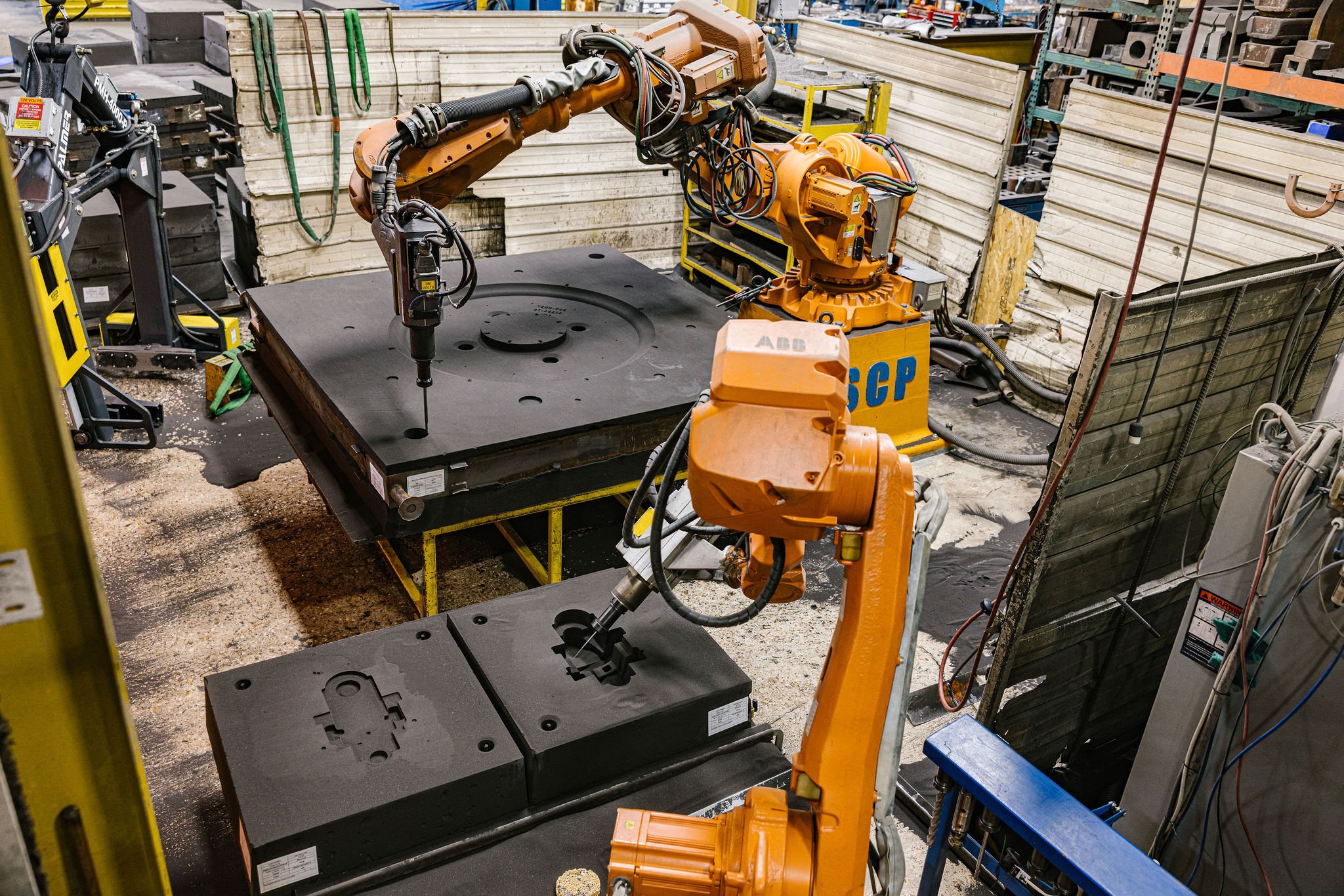

Using four advanced ABB Robotic Molders, we produce molds in a fraction of the time compared to traditional methods. This ensures faster turnaround times while maintaining high levels of precision and quality in each casting, so your projects stay on schedule.

-

Our hybrid mold process combines the precision of robotic milled sand molds with the innovation of 3D-printed sand cores. This hybrid approach allows for the creation of complex castings that require fine-tuned details, all within a single, streamlined design process.

-

Each mold we create is unique to the model, ensuring the elimination of costly pattern change fees or expensive machining operations. This allows us to provide customized, precise prototypes without the added expenses typically associated with traditional methods.

FAQs

Do you offer rapid prototyping services for custom metal parts in the U.S.?

Yes. One Off Castings provides rapid prototyping for custom metal parts across the U.S., specializing in fast-turn prototype castings, CNC finishing, and 3D sand printed tooling for OEMs, engineers, startups, and inventors..

How fast can you produce a prototype metal casting?

Lead times depend on part size, complexity, and tooling, but many prototype castings can be produced in as little as 14 once CAD files are finalized. We also offer accelerated options using 3D printed sand molds and rapid tooling.

What’s the difference between prototype casting and CNC machining?CNC machining is ideal for smaller runs or tight tolerances, while prototype casting is better for complex geometries, thicker sections, and production-like prototypes. Many projects combine both — casting for shape and CNC for precision features..