ABB Industrial Robots: 6700, 4400 & 4600 Series for Foundry & Manufacturing Automation

Published: June 5, 2025 | Reading Time: 6 minutes

ABB Robotics, headquartered in Zürich, Switzerland, has been at the forefront of manufacturing automation for over five decades. As a division of the ABB Group, it sets the global benchmark for precision-engineered robots tailored for diverse industrial environments. From heavy-duty foundries to high-speed CNC machining, ABB robot automation delivers unparalleled efficiency, accuracy, and safety.

What Are ABB Industrial Robots?

ABB industrial robots blend robust mechanical design with AI-driven software to deliver elite-level precision and adaptability. These cutting-edge machines handle complex tasks with positional accuracy as fine as ±0.02mm. Designed for demanding applications, ABB robots thrive in high-volume manufacturing, custom casting, and precision machining environments.

Why Choose ABB Robots for Manufacturing Automation?

Ultra-High Accuracy: Advanced servo control systems and high-resolution encoders ensure reliable, pinpoint positioning.

Built for Harsh Environments: Cast aluminum frames, sealed cables, and IP65/67 ratings enable operation in dusty, humid, and high-temperature zones.

Smart Automation Software: Tools like QuickMove and TrueMove optimize motion paths in real-time.

Industry 4.0 Ready: Seamless cloud connectivity supports live analytics and predictive maintenance.

Quick Answers: ABB Industrial Robot FAQ

What industries use ABB robots?

Automotive, aerospace, electronics, foundry, packaging, and general manufacturing.

How much can ABB 6700 robots lift?

Over 400 pounds with a reach exceeding 120 inches.

What makes ABB robot automation stand out?

Precision (±0.02mm), rugged construction, integrated vision, and AI-ready software systems.

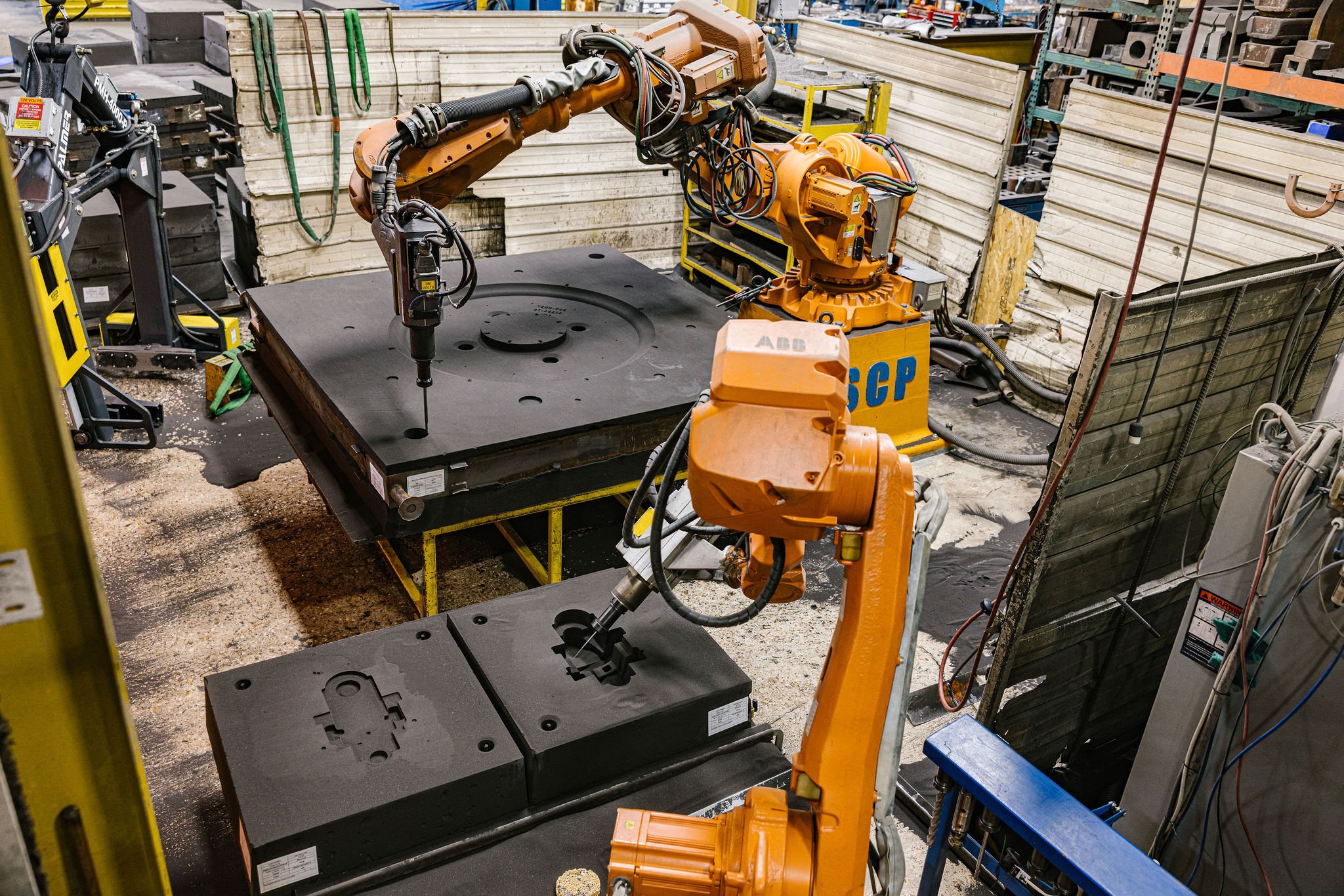

One Off Castings ABB Robot Fleet

ABB's Robotic Fleet at One Off Castings

At One Off Castings, we’ve deployed ABB’s most advanced robots to enhance product quality, minimize manual labor, and meet the tightest tolerances. Our fleet includes:

ABB 6700 Series: Heavy-Duty Foundry Robotics

Payload: 400+ lbs

Reach: 120+ inches

Protection: IP67-rated, built for foundries

Accuracy: ±0.1mm

Key Applications:

Iron casting transport, CNC finishing, mold handling

ABB 4400 Series: The Versatile Workhorse

Payload: 130+ lbs

Reach: 70+ inches

Versatility: High

Key Applications:

CNC machine loading, inspection automation, inter-process transport

ABB 4600 Series: Precision Specialist

Payload: ~90 lbs

Reach: ~100 inches

Protection: IP67

Key Applications:

Surface grinding, final inspection, delicate assembly work

ABB Robot Series Comparison

Model Max Payload Max Reach (in) Best Use Case Protection Rating Accuracy ABB 6700 400+ lbs 120+ Foundry casting, heavy machining IP67 ±0.1mm ABB 4400 130+ lbs 70+ Mid-range CNC & inspection IP67 ±0.07mm ABB 4600 90 lbs 100 Precision placement, finishing IP67 ±0.05mm

Advanced ABB Robot Technologies

QuickMove Motion Optimization

This system reduces cycle time by up to 25% without compromising precision or increasing mechanical wear.

TrueMove Path Accuracy

Ensures robots follow exact programmed paths despite variable speeds or payloads.

Integrated Vision Systems

Allows robots to recognize part orientation, perform visual quality checks, and adjust positioning in real-time.

Why ABB Robots Excel in Foundry Automation

Heat-Resistant Design: Reliable performance in extreme thermal conditions.

Consistent Precision: Maintains tight tolerances even under heavy payload stress.

Flexible Reprogramming: Easily adapts to new casting shapes and processes.

Future-Ready Automation: The ABB Advantage

Cloud & Analytics Integration: Use ABB Ability for predictive analytics and system health.

AI-Enhanced Learning: Robots improve autonomously through continuous data analysis.

Sustainable Operations: Energy-efficient systems reduce environmental impact.

Final Thoughts: Invest in Smarter Automation with ABB

Integrating ABB robots isn't just an upgrade—it's a strategic move toward precision, scalability, and next-generation automation. At One Off Castings, we’ve harnessed ABB automation to achieve consistent accuracy and unmatched efficiency.

Unlike traditional foundries, we integrate robotics from day one—so you get consistent, repeatable quality on every casting, from prototype to production of each one-off low-volume casting.

With ABB, you gain more than hardware; you gain a smart system that cuts downtime, maximizes throughput, and adapts with your evolving production needs.

Ready to modernize your casting operations?

Request Automation Consultation | View ABB Robot Capabilities | Schedule Facility Tour

Meta Title:

ABB Industrial Robots: 6700, 4400 & 4600 Series for Foundry & Manufacturing Automation

Meta Description:

Explore ABB industrial robots—6700, 4400 & 4600 series—for precision manufacturing and foundry automation. Learn about specs, use cases, and ROI.