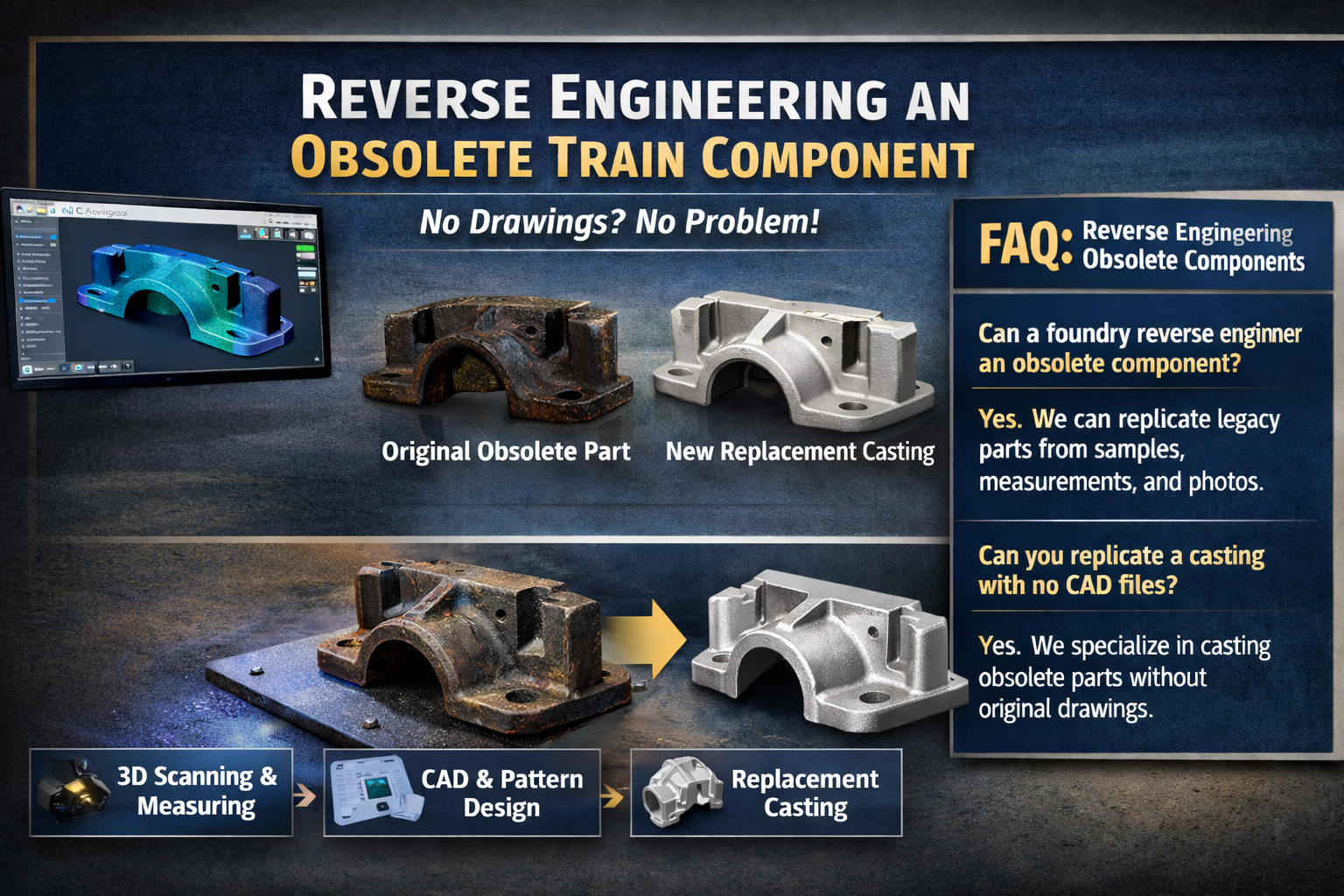

Case Study: Reverse Engineering an Obsolete Train Component (No Drawings Required)

When critical parts are discontinued, equipment downtime can escalate quickly — especially in rail and industrial environments where reliability matters.

In this project, One Off Castings helped a customer replicate an obsolete train casting using a reverse engineering workflow that required no original drawings, reduced pattern cost, and restored performance without redesigning the assembly.

Project Snapshot

Industry: Rail / Transportation Maintenance

Part Type: Obsolete Train Component (Casting)

Service: Reverse Engineering + Low-Volume Casting

Quantity: Low-Volume Replacement

Documentation Provided: None (No CAD / No Drawings)

The Challenge

The customer needed a replacement casting for a legacy train component that was no longer supported by the original manufacturer. The part was critical to performance, but traditional sourcing routes were no longer available.

Key constraints included:

• OEM replacement parts were unavailable

• No CAD model or engineering prints existed

• Traditional pattern development would be costly for a small run

• Equipment downtime increased urgency

• The replacement needed to match original geometry and fit

The Approach

One Off Castings built a replication strategy using the customer’s existing part sample and a streamlined reverse engineering process.

Part Review + Critical Feature Identification

We evaluated the sample component to identify critical geometry tied to fit and function.Reverse Engineering Workflow

Using measurement and scan-based methods, we rebuilt the part geometry and created a castable design without needing original drawings.Pattern Strategy for Low-Volume Production

Rather than using a high-cost traditional tooling approach, we selected a pattern strategy aligned with low-volume production to reduce unnecessary cost and lead time.Casting Production + Verification

The replacement casting was produced and verified for dimensional compatibility with existing equipment.

The Results

The final component enabled the customer to restore operations without redesign, new equipment, or OEM sourcing.

Outcome highlights:

• Functional replacement for an obsolete train component

• Lower cost by avoiding unnecessary pattern expenses

• Faster turnaround versus OEM sourcing or redesign

• Repeatable replacement solution for future maintenance cycles

Why This Matters

Many manufacturers and maintenance teams face the same issue: equipment that still works — but can’t be repaired because replacement parts are obsolete.

One Off Castings supports reverse engineering and replication for:

• Obsolete components

• Discontinued OEM parts

• Short-run replacement castings

• Legacy parts with no CAD or drawings available

Need an Obsolete Part Replicated?

If you have a discontinued component and only a sample part is available, we can help evaluate the best path forward.

Request a quote to discuss reverse engineering support and low-volume replacement casting.

FAQs

Can a foundry reverse engineer an obsolete component?

Yes. One Off Castings provides reverse engineering support for obsolete components by working from a physical sample part, photos, measurements, or partial drawings. This allows legacy parts to be reproduced even when OEM replacements are unavailable.

Can you replicate a casting without CAD files or original drawings?

Yes. Many legacy and discontinued cast parts can be replicated without CAD or original drawings using sample-based reverse engineering and low-volume pattern development for replacement casting.