From Digital to Metal: The Future of Prototype & Low-Volume Casting is Here

In the world of manufacturing and product development, turning a digital design into a physical metal part has often been a slow and expensive process. Traditional casting methods require creating a pattern or "tooling," a significant upfront investment in both time and money. This has long been a major barrier for innovators, engineers creating prototypes, and businesses needing small production runs.

But what if you could skip the tooling process entirely?

At One Off Castings, we're revolutionizing the foundry industry by bridging the gap between digital design and physical reality. Our state-of-the-art process makes custom, one-off, and low-volume metal casting more accessible, faster, and more affordable than ever before.

The Old Problem: The High Cost of Tooling

For decades, if you needed a custom cast part, you had to commit to:

High Tooling Costs: Creating a physical pattern from wood, plastic, or metal is a skilled, labor-intensive process that can cost thousands of dollars.

Long Lead Times: The design, fabrication, and delivery of this tooling can add weeks or even months to your project timeline.

Lack of Flexibility: Once the tool is made, design changes are difficult and expensive to implement.

Inefficiency for Prototypes: The high cost makes it impractical for single prototypes or very small batches.

This old model simply doesn’t work for the fast-paced demands of modern innovation.

The One Off Castings Solution: Robotic Sand Mold Milling

We do things differently. Instead of building a physical pattern, we mill your mold directly from a sand block using your CAD file.

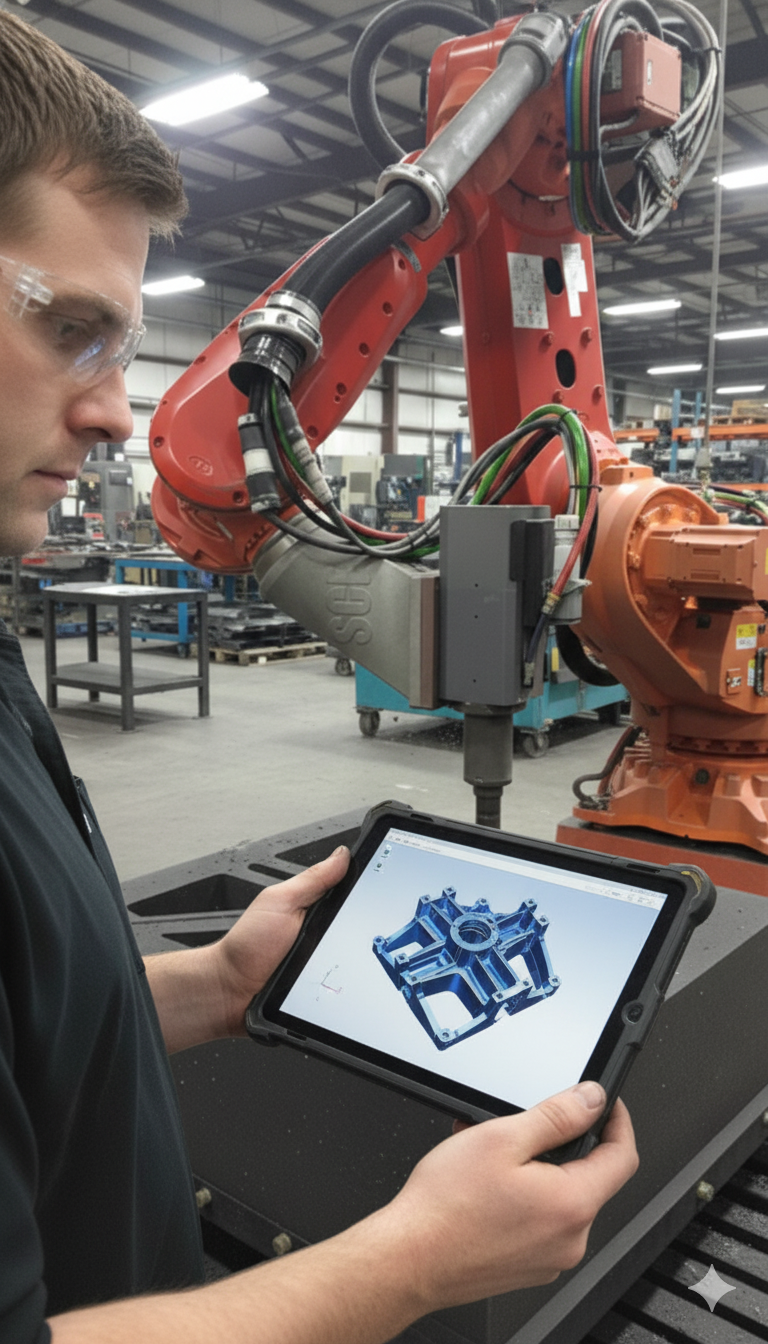

(Insert the image you provided here) Image Alt Text: An orange KUKA industrial robot arm precisely milling a complex sand mold for a custom metal casting at the One Off Castings facility.

Our process is simple and powerful:

You Send Us Your Design: We work directly from your 3D CAD files (like .STL or .STEP).

Robotic Precision: Our advanced robotic arms get to work, precisely milling the mold cavity directly into a block of foundry sand. This subtractive manufacturing process is incredibly accurate, capturing even the most complex geometries.

We Pour Your Metal: Once the mold is complete, we pour your chosen alloy to create your final part.

Fast Delivery: With no tooling to wait for, we can move from digital file to finished metal part in a fraction of the time.

Why Choose a Tool-Less Process?

The advantages of our robotic milling technology directly address the pain points of traditional casting.

Eliminate Tooling Costs: This is the single biggest benefit. By removing the need for a physical pattern, we slash your upfront investment, making single prototypes and small runs economically viable.

Accelerate Your Timeline: Get your parts in days, not months. This speed is critical for rapid prototyping, fit-testing, and getting your product to market faster.

Design Freedom & Flexibility: Need to tweak your design? Just send us the updated file. We can easily mill a new mold without the cost and delay of modifying a physical tool.

Unmatched Complexity: Our 6-axis robots can create complex shapes, deep pockets, and intricate features that are difficult or impossible to produce with traditional pattern-making.

Ready to Bring Your Design to Life?

Stop letting traditional manufacturing bottlenecks slow you down. Embrace the speed, precision, and cost-efficiency of modern casting technology.

Contact One Off Castings today for a free quote on your project. Let's make your vision a reality.